Scale up a peak only to push the boundaries

B-Uhr is one of the must-haves for men to wear. Its simplistic yet majestic dial is amply satisfying for those harboring a pilot dream. In awe, we take care of every noteworthy detail.

Swiss movements. It is essential for each and every Jenova Watch to come with a Swiss-made movement.

The JW1747001 Classic Pilot Watch uses the ETA2824-2 movement, officially acknowledged as one of the most stable Swiss movements, with absolute precision, reliable time-keeping and ideal power reserve.

NICKEL-PLATING FOR A VINTAGE TEXTURE

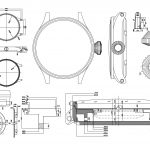

In different periods by different manufacturers, B-Uhr is made with different materials such as nickel-plated copper, alloy, stainless steel. With the passing of time, the dull colour of metals is given an extra layer of sedation to its sheen. We resort to stainless steel and the fine craft of abrasive blasting to restore the watchcase to its former WWII radiance.

THERMAL BLUING OF WATCH HANDS

Thermal Bluing refers to thermally treating the watch hands, a special craft of metal surface treatment that heats up the steel component to 300 degrees Celsius (540 degrees Fahrenheit) for surface oxidation till it turns azure blue, then light blue after the quenching process.

In watch-making workshop, there is one specific artisan responsible for manual thermal bluing of watch hands. He needs to have an acute judgment over colour changes. He needs to duly stop the heating of watch hands when the colour is in its best lustre. The thermal bluing instrument is neither big nor complex. Basically it consists of a heating worktop and a bracket for watch hands. The latter can avoid burns by the worktop when one moves the watch hands. Worth noting is that on a worktop that can accommodate 20 brackets, only two brackets can be placed in one session, according to the artisan. That means only two watch hands can be processed in one session. The reason is that colours change fast during the thermal treatment. Too light or too deep, the blue is not the right blue. The best colour sheen can be gone in fleeting seconds.

During the process, colours change so fast that if the heating worktop is fully occupied by brackets, the artisan could not possibly remove all the hands in a timely manner. As only two can be handled in one session, one can be getting ready as the other is still being treated. Then the one ready can be removed and replaced by a new hand for the thermal treatment. Then the timing would be about right for the other hand to be finished. Such cycle of work takes good rhythm. Different brands may require a different flow of work. For instance, when Glashütte Original screws undergo thermal bluing, the screw is placed one-by-one on the thermal soldering iron (the heating worktop). The artisan needs to refer to a Pantone to create the right blue colour required for Glashütte Original. During the thermal process, all kinds of blue shades will appear. As for which blue is the most appealing, different brands will have different standards. The practice of earlier independent watchmakers can also be adopted in that a specific blue steel shade can be used as a symbol for a certain brand. Is it worth training a high-caliber talent to achieve these micro colour tones? This will depend on the brand’s pricing and self-requirement.

JW1747001 Classic Pilot Watch is made with a similar heating method for time to stream in a perfect azure blue, reflecting your insistence on oneself and life.

Simple but uncompromising details

In the early days, when pilots had to stay inside the cockpit of rickety yet open aircraft, they were forced to wear thick overcoats and gloves. So the special extra-long, extra-thick, ring-shaped closed strap was attached to the watch. The strap was studded and then fastened by rivets. The pilot wore the watch over their overcoat sleeve to conveniently check the time. Even if the watch buckle came undone, the watch would not easily slip off. The leather for the watchstrap was processed with vegetable tanning for an alluring sheen on the surface and a soft texture to withstand repeated bending.

The conical crown for large military watches allowed pilots to wind the crown despite thick padded gloves. Arabic numerals and hour markings all have night-time illumination for them to keep track of time even during unlit hours.